Homepage | Success Stories | Safe guidance for welding robots

Safe guidance for welding robots:

The igm iCAM-PRO

laser camera

Autonomous laser sensor based on a VC board camera

The challenge: Measuring

weld seams

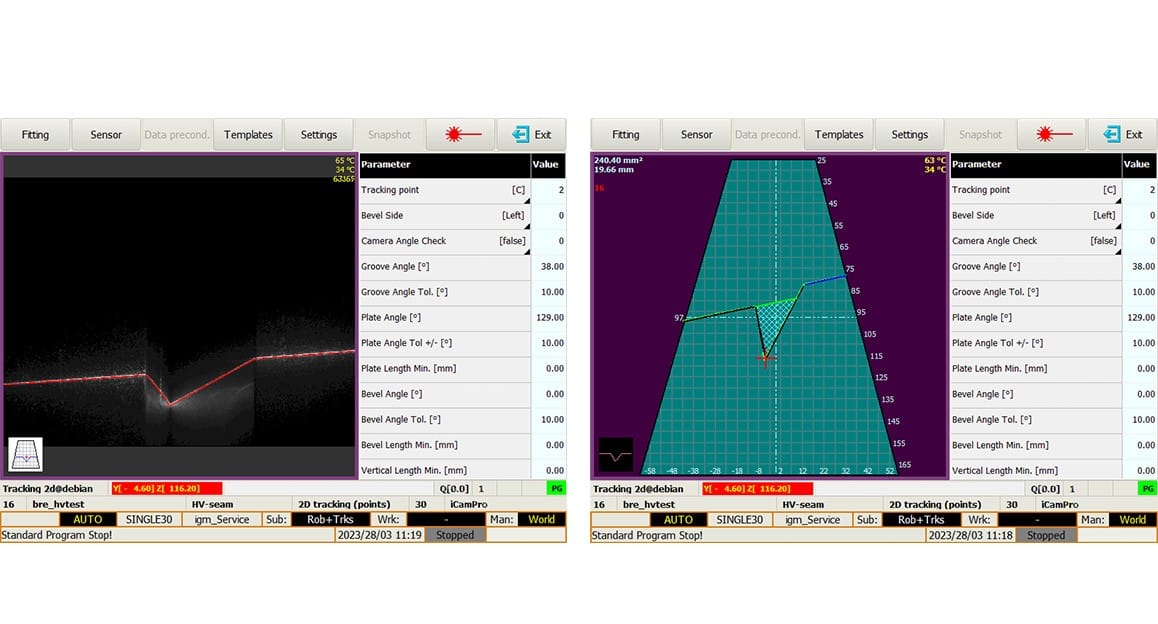

During arc welding processes, joint cross sections are to be measured and seam position and gap dimensions determined. The information is to be preprocessed directly in the sensor and transferred to the robot controller in real time.

The solution:

Smart laser sensor with

onboard pre-processing

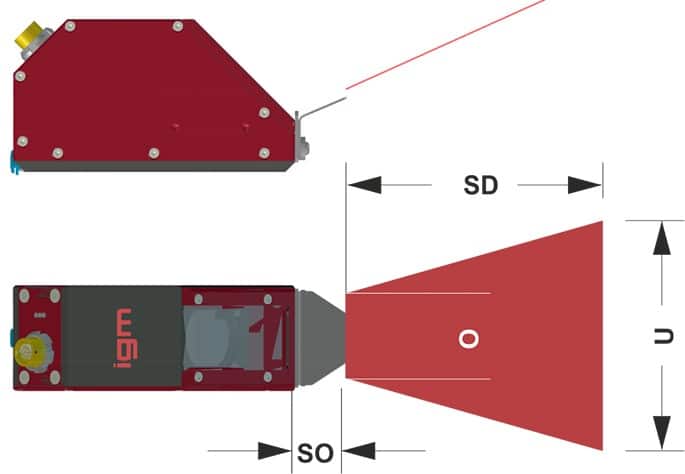

The iCAM-PRO laser camera combines the VCSBC nano Z-RH board camera with an in-house developed, powerful line laser module from igm and a special software for analyzing the seam information and calculating the trajectories. The programming is done directly via igm's K6 teach pendant.

Laser camera iCAM-Pro – igm Robotersysteme AG

Special feature of the igm laser camera is the onboard pre-processing of the scanned profiles.

Fully automatic robot guidance

for arc welding

The quality of a weld seam determines the strength and lasting reliability of the joint between two workpieces. Accordingly, the robot guidance, the adjustment of the welding parameters during the welding process, and the monitoring of the process quality are important. To enable this, igm Robotersysteme AG has developed an optical laser sensor. It tracks the weld seam so that the robot arm is always optimally positioned. The camera also measures the seam geometry and any gap dimensions that may occur, so that the welding parameters can be adjusted directly.

Pre-processing enables

robust data transmission

To increase process reliability, part of the evaluation of the scanned profiles is already preprocessed in the head of the laser camera. This reduces the amount of data to be transmitted and allows the use of more robust data transmission channels. This makes the iCAM-PRO much less sensitive to classic interference in welding robot technology. Especially for the laser sensor, igm has developed the profile evaluation software iScan. It makes it possible to adapt the evaluation to customer-specific seam geometries and thus to leverage the full potential of the iCAM-PRO.

Advantages of the igm iCAM-PRO

Compact design

For easy positioning, close

to the weld seam

Robust housing

Protected from dirt & moisture

Multiple models

Different viewing depths can be covered with sensor variants.

Direct integration

Operation directly via the K6 teach pendant from igm

Key Facts

Technology

3D laser scan

Challenge

onboard pre-processing

VC Vision Solution

VCSBC nano-Z RH

board camera

Fast onboard data processing with the FPGA of the OEM board camera.

One challenge in the

development of the igm laser sensor

iCAM-PRO was its

consistency at high speed, a large

programmable working range and a

deep field of view to ensure universal

use in industrial welding

processes.

development of the igm laser sensor

iCAM-PRO was its

consistency at high speed, a large

programmable working range and a

deep field of view to ensure universal

use in industrial welding

processes.

- Inside the laser camera, a VCSBC nano-Z RH board camera with remote VC MIPI® camera module is deployed for this purpose. It was combined with a line laser module with high-power laser developed by igm.

- The embedded vision system has an integrated FPGA core, which handles the line extraction in real time. Further pre-processing and analysis of the data is done with the igm-developed iScan software on the two ARM computing cores of the board-level camera.

- Due to the optimal interaction between FPGA and the further computing units, the system works extremely fast and efficiently.

- The embedded vision system with its CPU board measuring only 40 x 50 mm is very compact and has enabled the best possible integration into the laser sensor.

Computing power and industry-

optimized quality were key factors

During the development of the iCAM laser camera, it was crucial for igm Robotersysteme AG that the overall solution meets the highest requirements in continuous industrial use and under harsh environmental conditions. In addition, the computing power had to ensure onboard data preprocessing.

These requirements are met by the VC board cameras, which optimally integrate image sensors, dedicated computing units for data processing and interfaces. They:

These requirements are met by the VC board cameras, which optimally integrate image sensors, dedicated computing units for data processing and interfaces. They:

- provide long-term availability

- are industry-optimized

- are equipped with FPGA & ARM processors

- are easily programmable thanks to VC Linux

"Based on the VCSBC nano-Z RH, we were able to develop a laser sensor that allows us to better meet customer-specific requirements and increase process reliability in laser welding. The great expertise of the VC team, the open communication and the commitment to support have delighted us in our cooperation."

Dipl.-Math Robert Breitrückigm Developer

"The stable and fast pre-processing of the data directly on the VC board camera convinced us. It is also extremely compact and freely programmable thanks to the Linux operating system; this has significantly simplified its integration."

Dipl.-Ing. Michael Mokrickyigm Developer

Previous

Next

About igm Robotersysteme AG

As member of Global Welding Technologies, igm Robotersysteme AG looks back on a more than 50 years’ history as a leading company in welding automation. Since the 1980’s igm puts in its profound experience in designing, manufacturing and supplying of sensor controlled welding and cutting robot systems. Besides efficient overall solutions, also the development of individual customer related systems is done. More than 4000 robots systems are operating in industrial sectors worldwide.