How to use triangulation effectively

Measure components, determine gap and angle dimensions or check web edges: Triangulation with embedded vision and laser lines is used in numerous applications. The method works without contact and at a distance from the object under investigation, delivers very precise measurements and can be implemented cost-effectively thanks to the relatively simple set-up of the camera system.

The following points will show you whether Laser-triangulation with embedded vision is suitable for your application, what you should consider when making your choice and how we can significantly simplify your development with our modular offers.

How does laser triangulation with embedded vision work?

Laser triangulation describes a method for generating three-dimensional object data. A sensor detects the reflection of a laser line on the object to be measured and determines distance, size and outline from the angle of incidence. As a typical application, edges along a laser line are inspected using this method.

In addition, 2.5-D data of an object can be captured when the object or sensor moves against each other. From this data, 3D point clouds can be calculated - and thus provide the basis for precise three-dimensional measurements.

Typical applications in the industry

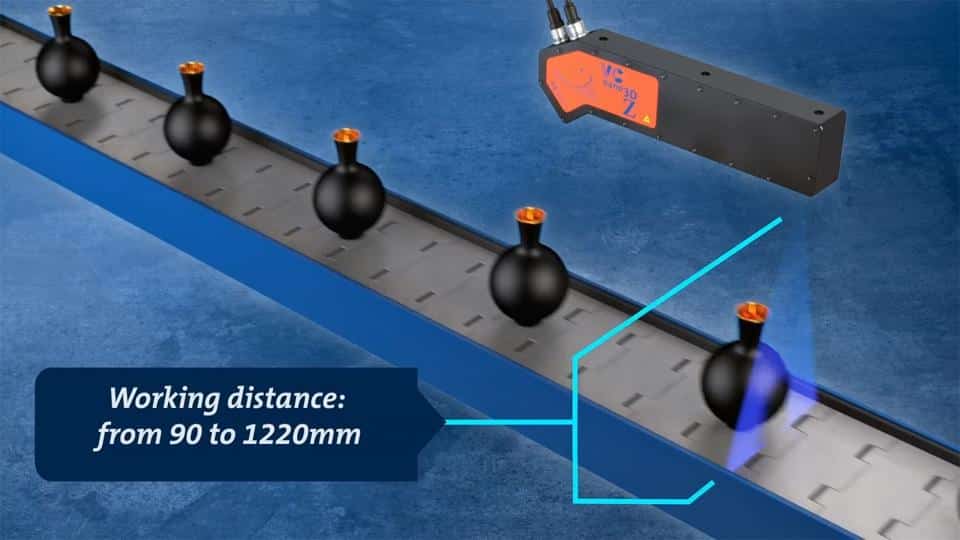

Laser triangulation is often used to measure gap dimensions or angles in the automotive industry, in mechanical engineering, in quality control or maintenance. Web edge measurements in the production of web and roll goods or for monitoring conveyor belts are also typical applications for triangulation with embedded vision. In addition, embedded vision systems from Vision Components are used to assess the position, size and height of components and for Pick&Place Applications. In the food industry, they are used to monitor fill levels and perform volume determination.

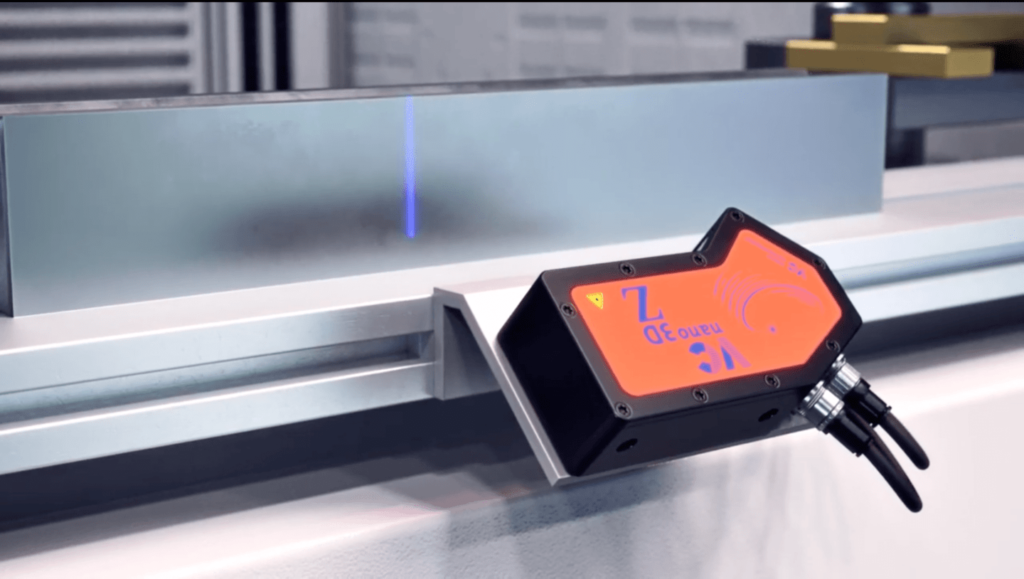

For manufacturers of press brakes and similar applications, stand-alone Laser triangulations systems offer a smart solution for Measuring and adjusting the bending angle in real time.The OEM inspection systems can be directly connected to the machine control system.

Advantages of laser triangulation with embedded vision for measurement and quality control

- Precise measurement results - even with large objects and surfaces

- Remote measurement - contactless and directly in the processing line

- Cost-effective: with scalable electronics with and without housing or using Vision Components ready-to-use solutions

- Fast data analysis - evaluation directly in the FPGA and thus optimal for mobile use, independent of PC systems.

- Long service life of lasers and cameras

How to develop the optimal application with laser triangulation

The relatively simple design of laser triangulation and the use of standard components enable fast and cost-effective development for a wide range of applications. The process is ideally suited for all surfaces where laser light cannot penetrate. Transparent glass or plastic containers, for example, cannot be measured by laser triangulation or can only be measured with great difficulty. Furthermore, the shading of the object should be taken into account: Due to the set-up, only surfaces can be captured from one perspective per camera. A test system provides information as to whether reflection and actual measurement results meet expectations.

Fast evaluation and easy start into development

Our VC Nano 3D-Z Series for laser profile measurement and other triangulation applications works with a powerful blue laser module and our proprietary Ambient Light Suppression Technology. The laser complies with protection class 2 and therefore does not require a housing. Due to very high light intensity and short pulse rates, the triangulation sensor works independent of ambient lighting and allows extremely short exposure times. This ensures robustness in industrial applications and mobile use.

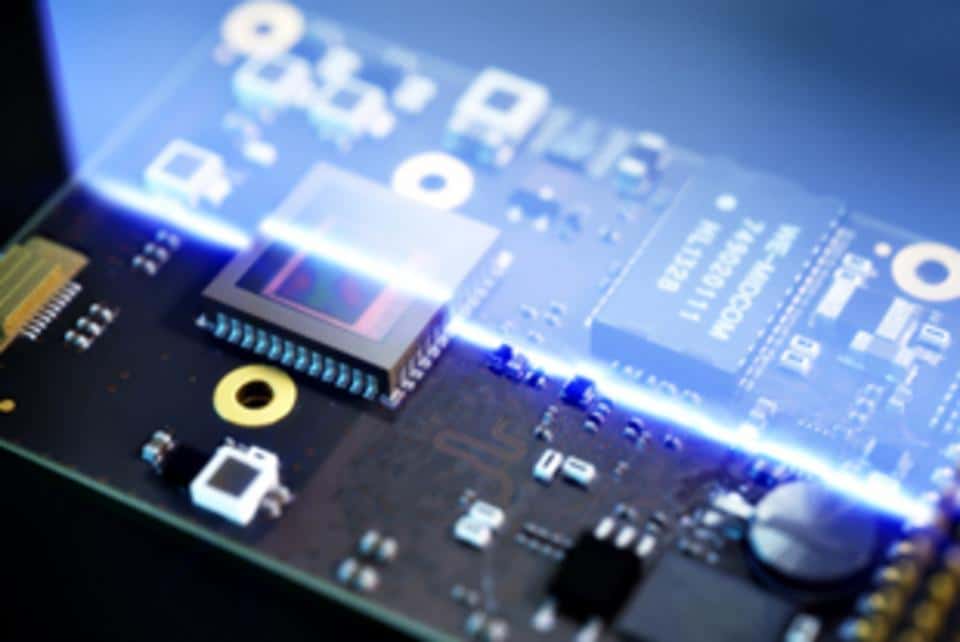

Vision Components offers flexible test systems including demo software to evaluate the suitability for your application and the performance of the solution: either based on our intelligent 3D Embedded Camera Systems, which are available as board cameras with or without housing, or as completely integrated solutions including optics and lighting. Your advantage: regardless of the depth of integration, hardware acceleration is always part of the hardware. For this purpose, the embedded vision systems are equipped with powerful FPGAs on which the pre-processing of the sensor data takes place. Here 3D point clouds are generated from the triangulation data.

The Vision Components lasertriangulations systems also have DualCore ARM processors. Their computing power and the Linux operating system are freely available for your specific application. Whether web edge inspection or angle measurement, gap dimension control or optical inspection for cracks and damage: numerous calculation models and analysis procedures can be carried out directly on the systems. The VC LIB with many pre-developed functionalities is the perfect starting point for the further development of your individual evaluations and applications.

VC nano 3D-Z: proven laser triangulation sensors for a wide range of measurement applications

Four integration options for the VC nano 3D-Z laser profile sensor: from ready to go to board camera

Are you interested?

Describe your project idea to us and together we will find the perfect solution for prototyping and the step to series production. Our experts are looking forward to your call or message!